Share This Story, Choose Your Platform!

Why Using Regular Air as Feed Gas in Ozone Generators Might Not Be the Best Choice

At Absolute Ozone, we often receive inquiries about operating ozone generators with regular air as feed gas instead of highly concentrated oxygen. It’s a valid question, and I want to clarify a valid question with a detailed response.

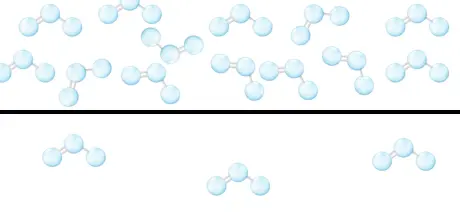

Using regular air as a feed gas in ozone generators may seem like a smart decision initially, but it has several significant drawbacks that affect performance, efficiency, and cost in the long run.

1. Electrode Sedimentation and Ozone Production Decline

One primary issue arises from the nitrogen content in regular air, specifically Nitric Oxide, which forms sediment-like coatings on the ozone cell electrodes. This sedimentation impairs the steady ozone production, leading to a decline in ozone production. Eventually, the electrodes need frequent cleaning and replacement—a time-consuming and expensive process.

2. Ozone Concentration Drop and Reduced Dissolution Efficiency

The ozone concentration typically drops significantly when using dry air as the feed gas. This drop can be up to 5-7 times in smaller ozone generators, making it nearly impossible to dissolve more than 10% of the total produced ozone in water. Consequently, the actual ozone production diminishes substantially due to the lower oxygen content in the air. For instance, a system having 10 g/h of ozone might only dissolve 0.3-0.5 g/h when using dry air. This substantial reduction in efficiency renders the use of dry air impractical.

O3 Concentration %wt |

Percentage of O3 dissolved in water |

|

1% wt |

10% |

|

3% wt |

20-30% |

|

5-7% wt |

50-70% |

|

8-10% wt |

80-90 |

|

10-14% wt |

95% |

|

14-22% wt |

97% |

3. Impact on Treatment Processes

Moreover, low ozone concentrations generated from regular air can significantly slow reaction times when treating solids or gases. This inefficiency makes the treatment process wasteful, time-consuming, and ultimately costly. Additionally, high-concentration ozone generators like our NANO unit cease ozone production when the concentration drops below 60%, rendering them ineffective with dry air.

4. Cost Considerations

Contrary to potential assumptions, the cost of an oxygen concentrator is comparable to that of an air dryer. Therefore, the perceived cost-saving advantage of using dry air is outweighed by the numerous issues it introduces. From decreased efficiency to increased maintenance costs and ineffective treatments, the financial benefits don’t add up.

In conclusion, while using regular air as a feed gas in ozone generators might seem plausible, the practical implications suggest otherwise. The drawbacks, including reduced ozone production efficiency, electrode sedimentation, slower reaction times, and increased operational costs, make it a less intelligent choice than highly concentrated oxygen.

At Absolute Ozone, we prioritize efficient and sustainable solutions for ozone generation, ensuring optimal performance and cost-effectiveness for our clients.