Share This Story, Choose Your Platform!

Unlock the Benefits of Ozone Use in CIP Systems

Cleanliness and efficiency are vital in the food and beverage industry, where effective sanitation can significantly impact product quality and safety. Clean-in-place (CIP) systems have revolutionized how these industries handle cleaning and disinfection, ensuring optimal hygiene levels. But there’s always room for improvement. Enter ozone technology, an eco-friendly alternative to traditional cleaning methods, offering numerous benefits in terms of efficiency, cost savings, and environmental impact. Ready to step into the future of cleaning? Read on to discover how ozone use in CIP systems can unlock the full potential of your CIP system.

Key Takeaways

Compared to traditional methods, ozone-based CIP systems offer environmental benefits, increased cleaning efficiency, and cost savings.

Ozone is a more reliable disinfectant for CIP systems than traditional disinfectants, with consistent performance under different conditions.

Proper selection, installation and maintenance of ozone generators are essential for optimal performance in CIP systems.

Understanding Ozone in CIP Systems

Ozone, a powerful and eco-friendly disinfectant, is increasingly employed in CIP systems to clean and disinfect process equipment in the food and beverage industries. Offering a range of advantages over traditional cleaning methods, ozone technology reduces water and chemical consumption, simplifies cleaning cycles, and even shortens washing times.

But how does ozone work, and how can it be integrated into existing CIP processes? We’ll explore the science behind ozone and its seamless integration into CIP systems.

The Science Behind Ozone

Ozone is a highly reactive oxidant that doesn’t form chlorinated organic compounds, making it a safer and more environmentally friendly option for cleaning and disinfection than chlorine dioxide. As a powerful oxidant, ozone effectively decomposes organic material and eradicates pathogens, making it an ideal sanitizer for CIP systems.

Here’s how ozone is generated and used for cleaning:

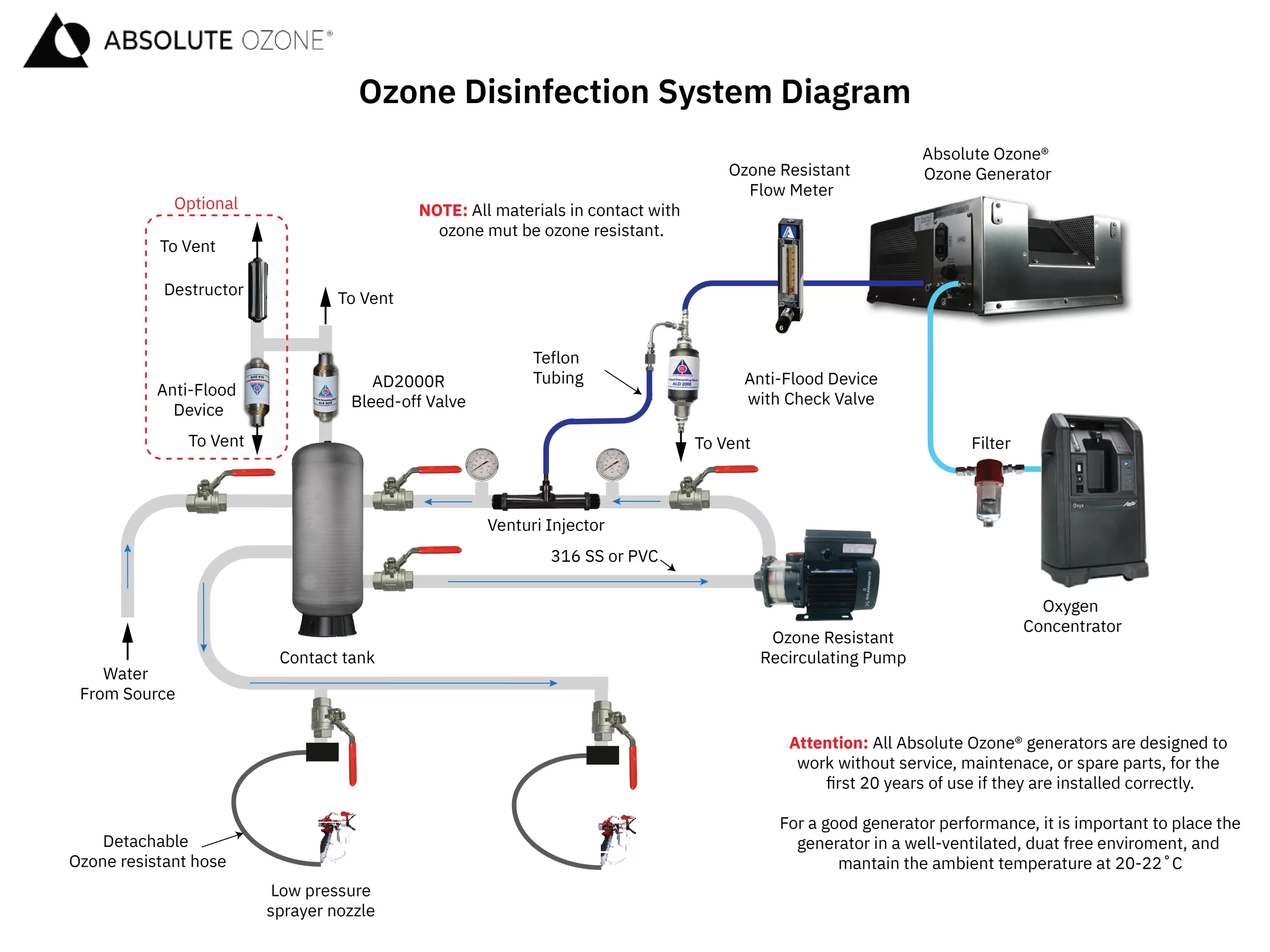

- Ozone is generated through an ozone generator that produces an electric discharge, converting oxygen into ozone gas.

- The ozone gas is first dissolved in water.

- It is then circulated through the equipment to be cleaned.

Unlike some traditional cleaning methods, ozone does not produce chlorinated organic compounds, offering a greener and safer alternative.

Ozone’s strong oxidant potential allows it to break down organic material in CIP systems through oxidation. The washing process consists of reactions with organic substances that break down these molecules into smaller components. Additionally, ozone produces no undesirable compounds and leaves no residual chemicals after use. This powerful disinfection capability makes ozone a popular choice for industries looking to upgrade their CIP systems.

Integrating Ozone into Existing CIP Processes

Incorporating ozone into existing CIP processes can lead to:

- Reduced water, chemical, and energy usage

- Simplified cleaning cycle

- Effective cleaning at lower temperatures

- Alternative to chlorinated sanitizers, peracetic acid, and hot water rinse

- Reduced water consumption for flushing

- Shorter system cool-down times

- Reduced environmental impact and resource consumption

Using ozone instead of conventional CIP significantly reduces the ecological footprint, making it an attractive option for industries looking to minimize their environmental impact. Ambient ozone monitors can help ensure the safety of the personnel.

A successful incorporation of ozone into an existing CIP process involves the following steps:

- Conducting a feasibility study

- Designing an ozone injection system

- Establishing ozone dosage and contact time

- Modifying CIP procedures

- Training personnel

- Monitoring and optimizing the system

With the right implementation, ozone can replace traditional disinfectants like quaternary ammonium compounds, offering a more eco-friendly and efficient cleaning solution for CIP systems.

Advantages of Ozone-Based CIP Systems

By harnessing the power of ozone in CIP systems, industries can enjoy a plethora of benefits. Ozone-based CIP systems offer environmental benefits, improved cleaning efficiency, and cost savings compared to traditional methods.

In the subsequent sections, the focus will be on how ozone reduces the environmental impact of CIP systems, enhances cleaning efficiency, and contributes to significant cost savings.

Environmental Impact

One of the most significant advantages of using ozone in CIP systems is its minimal environmental impact.

Ozone offers the following benefits:

- Reduces chemical and water usage, leading to more sustainable cleaning processes

- Powerful disinfection properties eliminate the need for harmful chemicals

- Fewer toxic byproducts are released into the environment

Furthermore, ozone-based CIP systems contribute to energy conservation by eliminating the use of hot water cycles and allowing for disinfection in cold water. With an increasing focus on environmental sustainability in industries, ozone presents a promising solution for cleaner and greener CIP systems.

Improved Cleaning Efficiency

Ozone’s rapid disinfection capabilities and its broad-spectrum biocidal properties make it a highly efficient cleaning agent. It has been proven to be more expeditious and effective in comparison to other disinfectants.

Ozone’s biocidal properties effectively eradicate:

- Bacteria

- Fungi

- Molds

- Inactivate viruses

Thus making it a highly effective cleaning agent.

Research studies have demonstrated the effectiveness of ozone as a cleaning agent in CIP systems across various industries, such as the wine industry and food processing. By implementing ozone-based CIP systems, Industries can benefit from:

- Improved cleaning efficiency

- Reduced cleaning cycle times

- Increased productivity

- Cost savings

Cost Savings

Ozone-based CIP systems can lead to significant cost savings through reduced water, chemical, and energy consumption. By eliminating the need for hot water cycles and reducing chemical usage, ozone helps industries save on water and chemical costs. Additionally, ozone’s cold sanitation method and reduced rinse steps contribute to decreased energy costs.

Apart from utility savings, using ozone in CIP systems also offers the following benefits compared to traditional cleaning and disinfection methods:

- Reduces running costs by eliminating the need for costly chemical detergents and sanitizers

- Provides economic benefits by lowering overall expenses

- Offers environmental benefits by reducing chemical usage and waste

By switching to ozone-based CIP systems, industries can achieve both economic and environmental benefits.

Comparing Ozone to Traditional Disinfection Methods

Ozone stands out as a highly effective disinfectant that outperforms traditional methods in terms of pathogen elimination and is less affected by external factors. This section will shed light on how ozone stacks up against traditional disinfection methods such as chlorine and heat, as well as the factors influencing its disinfection performance.

Effectiveness Against Pathogens

Compared to other disinfectants like chlorine and chloramine, ozone is more effective against a wide range of pathogens, including bacteria, viruses, and fungi. Its strong oxidizing capabilities render it capable of oxidizing crucial components of cells and cell membranes, thus inactivating microorganisms. Ozone’s higher disinfection efficiency is also evident in its superior Ct values (concentration x time) for pathogen reduction, demonstrating its effectiveness as a disinfectant.

Industries that rely on clean and sanitary conditions, such as food industries and pharmaceutical manufacturing, can greatly benefit from the superior disinfection capabilities of ozone in their CIP systems. By eliminating a wide range of pathogens more effectively than traditional disinfectants, ozone ensures a higher level of cleanliness and safety for these industries.

Factors Affecting Disinfection Performance

One of the advantages of using ozone as a disinfectant in CIP systems is its performance consistency under various conditions. Ozone’s disinfection performance is less influenced by factors like pH, making it a more reliable option for CIP systems. This is in contrast to traditional disinfectants like chlorine, which can be significantly affected by changes in pH levels.

Temperature also affects the disinfection performance of ozone in CIP systems, with ozone proving more reliable and efficient at lower temperatures. This ability to perform consistently under different conditions makes ozone a preferred choice for industries seeking to maintain optimal disinfection performance in their CIP systems.

Industrial Applications of Ozone in CIP Systems

Ozone technology is not just a promising concept – it’s already being successfully used in various industries, including food and beverage production and pharmaceutical manufacturing, for CIP system sanitation.

The subsequent sections will examine the real-world applications of ozone in these industries and highlight the benefits it offers.

Food and Beverage Industry

In the food and beverage industry, ozone is used to improve process efficiency, reduce chemical usage, and prevent flavor alteration in products. By employing ozone as a disinfectant, these industries can efficiently sanitize surfaces without leaving any residues or by-products that could affect flavors. Ozone’s gentle disinfection properties also make it suitable for use at high levels without impacting taste or appearance, ensuring that product quality is preserved.

Moreover, ozone technology offers significant environmental benefits in the food and beverage industry, as it reduces chemical and water consumption, leading to more sustainable cleaning processes. With the growing emphasis on environmentally friendly practices, ozone technology presents a promising solution for food and beverage manufacturers looking to improve their CIP systems and reduce their ecological footprint.

Pharmaceutical Manufacturing

Pharmaceutical manufacturers also benefit from ozone’s lack of residual and efficient disinfection capabilities in their CIP systems. By generating ozone on-site and using it to clean and sanitize equipment, these manufacturers can eliminate the need for chemicals or hot water, reducing the environmental impact and resource consumption associated with traditional CIP systems.

Additionally, ozone’s powerful disinfection properties ensure that pharmaceutical products maintain their integrity and quality by effectively killing bacterial growth and pathogens on contact. With its numerous benefits and growing adoption in various industries, ozone technology is poised to revolutionize the way CIP systems are designed and operated in the pharmaceutical manufacturing sector.

Selecting and Implementing an Ozone Generator

Choosing the right ozone generator and proper installation and maintenance are crucial for successful implementation in CIP systems. This section will address the factors to consider when selecting an ozone generator, in addition to the considerations for its correct installation and maintenance.

Types of Ozone Generators

Ozone generators come in various types, including air-cooled and water-cooled systems. Each has its unique set of advantages and considerations, making it essential to assess your specific needs when deciding between them.

Air-Cooled Ozone Generators:

- Efficient Production: Air-cooled ozone generators are known for their efficiency in ozone production, meaning they generate ozone effectively.

- High Ozone Concentration: These systems typically offer higher ozone concentrations, which can be beneficial in applications requiring highly concentrated ozone.

- Low Operating Costs: Air-cooled ozone generators often have the advantage of low operating costs, which is a crucial consideration for cost-conscious applications.

- Maintenance-Free: These systems may also require less maintenance, reducing long-term maintenance expenses.

Water-Cooled Ozone Generators:

- Water Consumption: One of the primary issues with water-cooled ozone generators is that they require a constant water supply to cool the ozone generation process. This can be a challenge in areas with water scarcity.

- Additional Maintenance: Water cooling systems may require more rigorous and costly maintenance due to water circulation and the need to prevent issues like sediment buildup.

- Operating Costs: Water-cooled ozone generators can be more expensive to operate due to energy and water consumption, which should be taken into account when considering the budget.

When comparing air-cooled and water-cooled ozone generators for your specific requirements, consider the following factors:

- Price

- Oxygen source

- System components

- Ozone production

- Safety

- Durability

By carefully evaluating these factors and utilizing commercial ambient ozone monitors, industries can choose the appropriate ozone generator for their specific CIP system requirements and ensure optimal performance.

Installation and Maintenance Considerations

Proper installation and maintenance of ozone generators are essential for optimal performance and longevity in CIP systems. To prevent common installation errors, follow these guidelines:

- Do not underestimate the required ozone generation capacity.

- Position injectors below the ozone generator.

- Ensure material compatibility.

- Provide adequate maintenance.

It is crucial to follow the manufacturer’s guidelines and seek professional assistance when necessary.

Regular maintenance of ozone generators accessories, such as check valves pump and oxygen generators servicing, is also key to ensuring their effectiveness and prolonging their lifespan. By adhering to proper installation and maintenance practices, industries can successfully implement ozone technology in their CIP systems and reap its numerous benefits.

Summary

In conclusion, ozone technology offers a powerful and eco-friendly alternative to traditional cleaning methods in CIP systems. With its numerous benefits, such as reduced environmental impact, improved cleaning efficiency, and cost savings, ozone is revolutionizing the way industries approach sanitation and hygiene. By selecting the appropriate ozone generator, following proper installation and maintenance practices, and harnessing the full potential of ozone technology, industries can elevate the performance of their CIP systems and contribute to a greener and more sustainable future.